NANOMIZER Inc.

Generator

The type of generator used depends on the target material and application.

There are several types of generator available, such as the collision-type (closed-drain type), flow-through type (orifice shape) etc. A suitable one will be selected based on actual trial and evaluation.

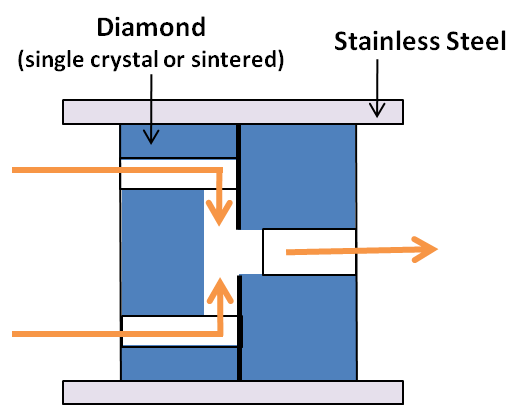

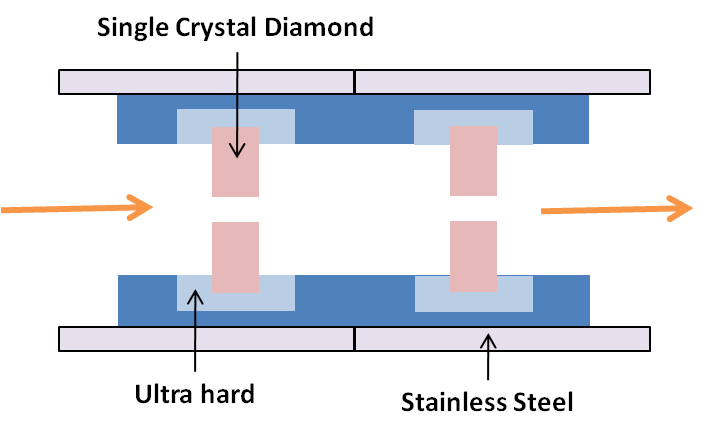

■ Collision-Type Generator

|

This is a highly-efficient generator structure that can be used for emulsification, dispersion or crushing purposes. As the pulverization energy is generated entirely within the diamond disk, processing can be done with extremely low contamination. |

|

Most powerful among all Nanomizer nozzles (used widely for pulverization, dispersion and emulsification purposes). Simple design with 2 holes opened in the diamond disks. A drain connects the holes on one side of the disk and this drain is closed by fitting the 2 disks together. |

|

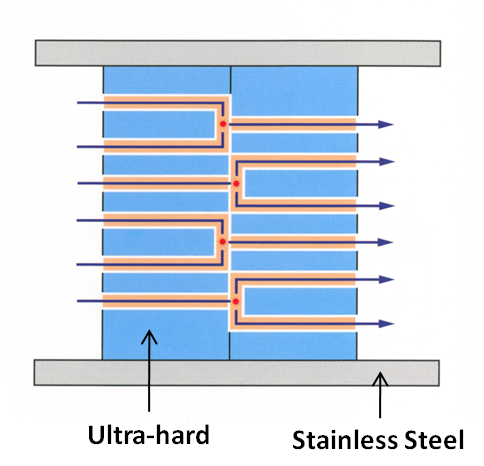

Same principle as the single opening type but with multiple openings. (mainly used in production models for emulsification and dispersion purposes) |

■ Flow-Through Type Generator

|

Simple shape formed by 2 orifices |

|

| Structure that allows passage through 2 orifices. As the diameter differs between the IN and OUT orifices, pulverization energy is generated between the 2 orifices. This is mainly used for emulsification, dispersion and separation purposes. |

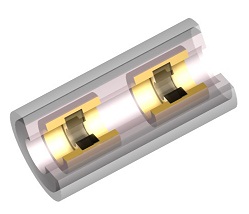

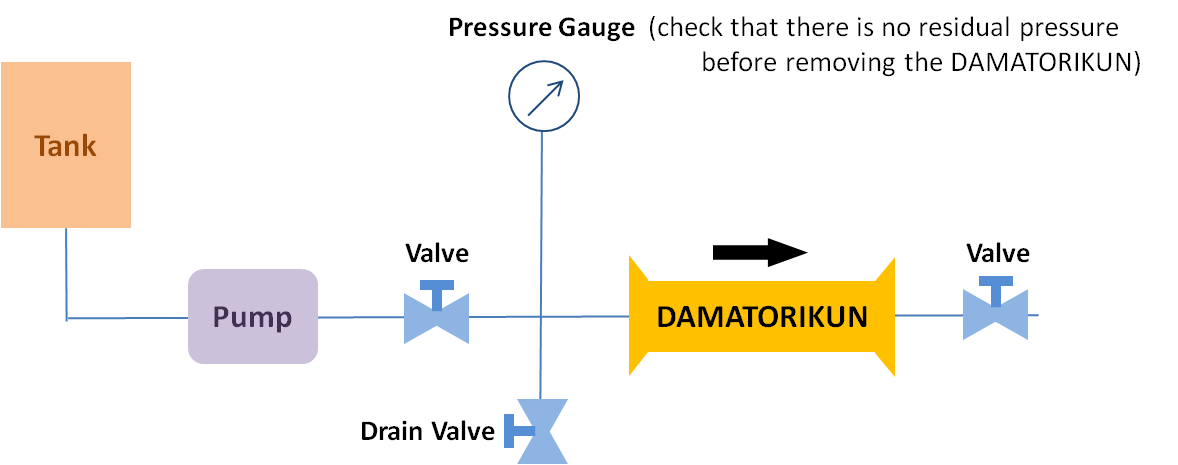

■ DAMATORIKUN

Use the DAMATORIKUN

for stirring, mixing, preliminary dispersion

and preliminary emulsification!

|

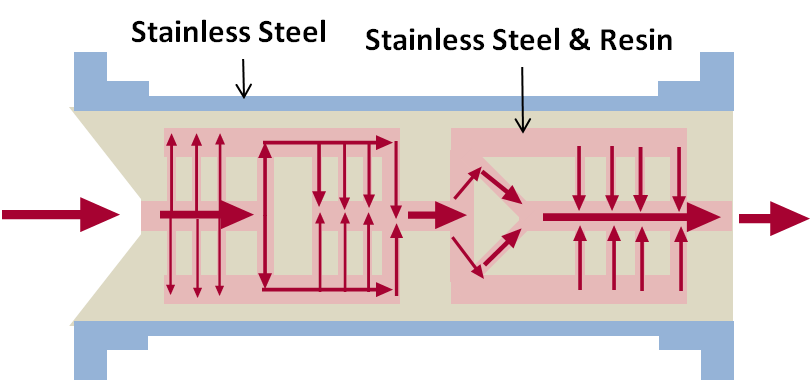

DAMATORIKUN has a unique and special structure that reduces the lumps that occur in powder slurry to support homogeneous and effective processing. It works by simply installing one in the production line and is most suitable for mixing liquids, paste, pre-dispersion of powder agglomerate and homogeneous dispersion of liquid-in-liquid. |

【 Installation Example 】

|

|

Creates effective flow in spaces with Pulverization using energy from shearing |

Turbulent flows are generated when Effective and homogeneous mixing is |