NANOMIZER Inc.

Principle of Pulverization

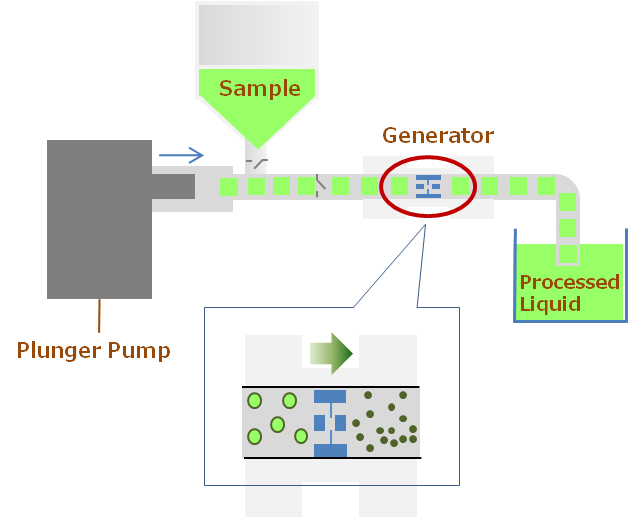

■ Principle of Pulverization using Nanomizer

The fundamental principle of Nanomizer is to generate very minute flow channel of φ30 to 400 μm through an ultra-hard material made mainly of a single crystal diamond known as a generator. By forcing the specimen through the generator at a very high pressure of up to 200 MPa using a plunger pump, a high-speed flow is thereby generated. This pulverizes the specimen by creating a cavitation effect in addition to the physical forces of compression, shearing, impact and abrasion that are generated.

■ Generator Characteristics

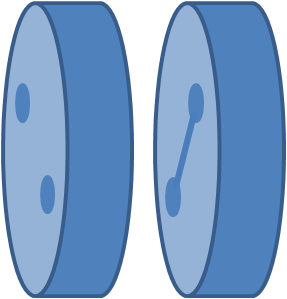

A generator is made of an ultra-hard material consisting of mainly diamond with a very small opening (nozzle) of Φ30~400μm. There are several types of generators available and one of the commonly used “Collision Type” generator is shown in the diagrams below.

(Generator details)

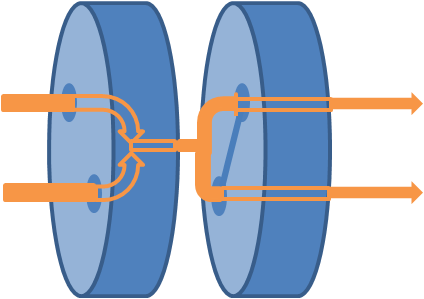

| Generator Internal Disks | Illustration of Liquid Flow |

|

|

Nozzle Material |

|

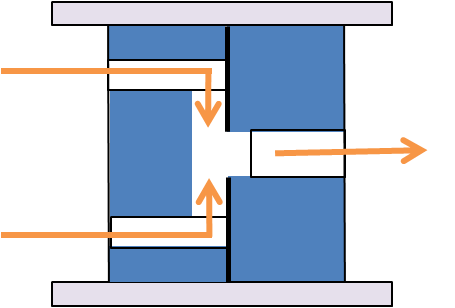

| Disk Cross-Sectional Diagram | |

|

|

pulverization energy is concentrated at the collision point where the liquid flows collide in the internal drain. |

|

Highly-efficient generator structure that can be used for emulsification, dispersion or crushing purposes. In addition, there is no gushing flow after the nozzle in the generator. As the high-speed flow is generated and terminated all within the diamond nozzle, contamination and wear and tear outside of the nozzle is reduced drastically.